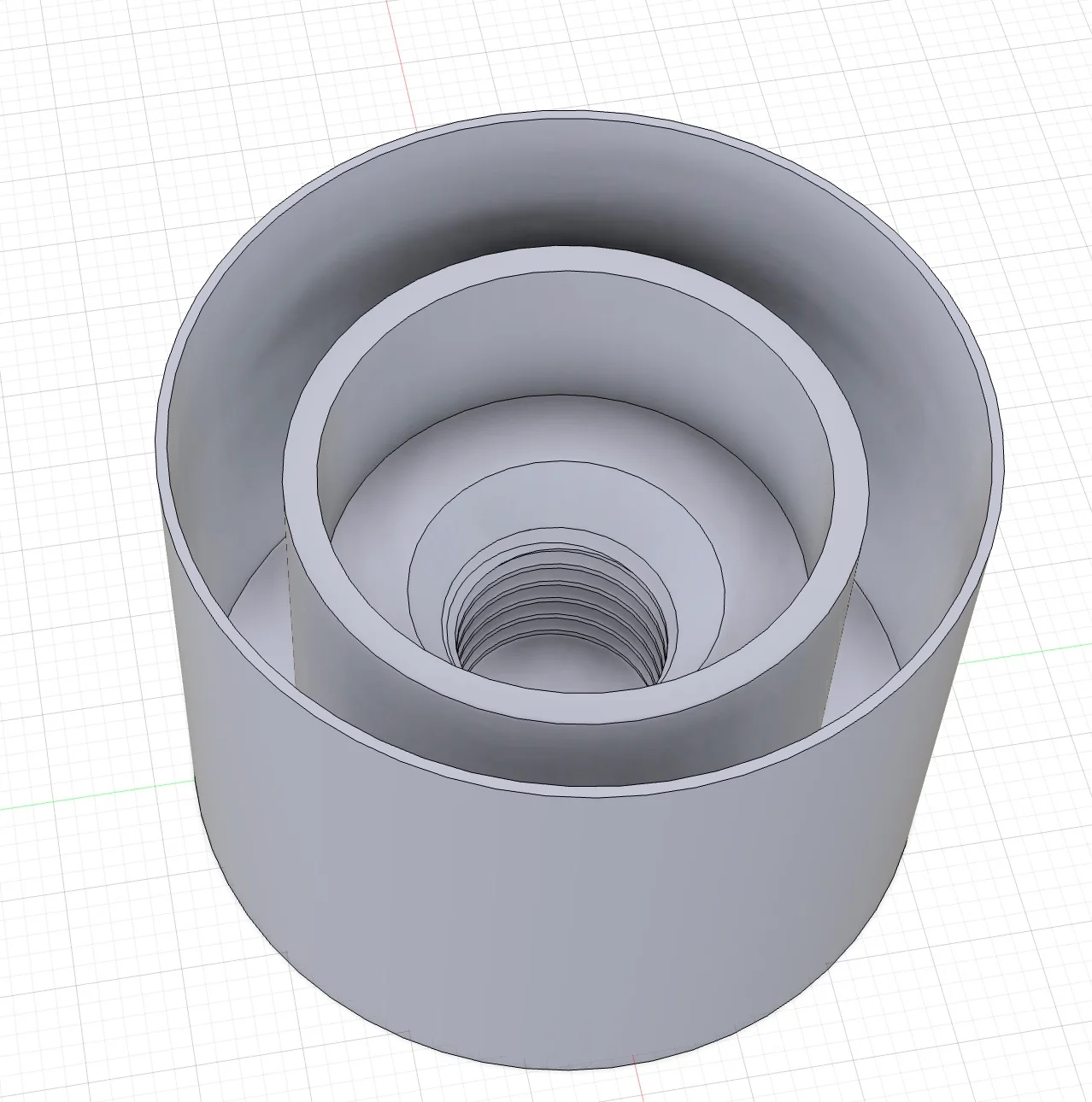

Cast Resin Vent Plug

Surfboards and paddleboards require pressure equalization to prevent delamination from temperature changes. This project focused on creating a reliable vent plug that could be made with simple shop materials. Prior to this, we had been resin 3D-printing the vents, which worked great; however, it was costly and time-consuming.

First, a 3D-printed part is printed, then silicone is poured into that mold. Once cured, the 3D-printed piece is discarded. While working on a surfboard, extra resin (which normally is discarded) can be poured into the silicone mold. Once cured, it is popped out, cleaned up, tapped, and ready to go into the surfboard.

Impact

The optimized manufacturing process significantly reduced waste and improved visual consistency (allowing for color matching). The vent plugs are now a standard component across our product line.

- Reduced material waste

- Achieved consistent color across production